March 05, 2021

Many companies are structured and very competitive in producing large numbers. The administrator of Officine Meccaniche Marcucci explains that producing from 1 to 500 pieces becomes a problem both in terms of costs and time.Officine Meccaniche Marcucci has equipped itself to be one of the most competitive companies at this juncture by investing in machines that are less fast in the production phase but quick in the tooling and programming phase, a fundamental combination for the production of small batches, applied through the innovation of CNC milling. for the production of components and mechanical parts made to design in small and medium series.

Explain what is CNC milling

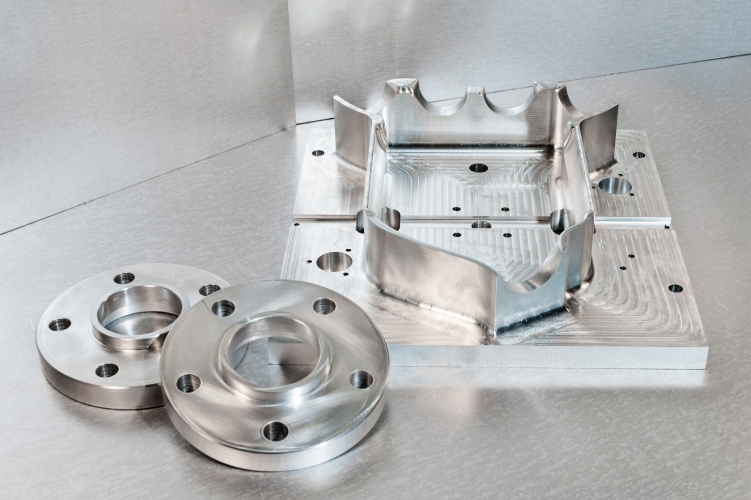

The administrator Marcucci gives the meaning of milling: a mechanical process that allows the modeling of pieces in complex shapes, performed by chip removal thanks to the application of tools with defined geometry and rotary motion called cutters, where through their circulatory movement they actuate mechanical processing of metal.

Machines are required that must allow the reduction of multiple placements of the piece, for this reason Officine Meccaniche Marcucci uses multi-axis machining centers that allow to work on several faces simultaneously.

Officine Meccaniche Marcucci provides two stages of mechanical processing in small and medium series milling, which are:

1. Roughing: takes place with the removal of material quickly and economically;

2. The finish: refers to the project commissioned to Officine Meccaniche Marcucci where the product conforms to dimensions, tolerances and surface roughness.

Milling, as the director Marcucci explains, is suitable for the production of components, made-to-measure parts made to drawings, and as regards our mechanical workshops it finds its application in small to medium production batches intended for multiple areas of use, we produce complete elements that meet the needs of the most varied product sectors, such as the general mechanics sector, the naval sector, the earthmoving sector, the hydraulic sector, the medical sector, the food and packaging industry, packaging.

An important factor in metal processing is the high attention to precision that our mechanical workshops use in the production of small and medium series parts.

For us the key points of our production are the following:

1. Choosing a correct tooling, it is always necessary to choose on the basis of the metals to be treated which are the most suitable tools to use: from the cutter, to the spindle, to the tips up to the taps;

2. Knowledge of the metal to be used in the CNC milling of particular components in small and medium series, since it is decisive in the choice of tools and above all we would like to emphasize that a specific metal can be more or less suitable for a specific project;

3. Definition of parameters, it is necessary to define well the number of spindle revolutions, rotation speed and feed, these are fundamental things because they affect the final result of the project that has been commissioned to us;

4. Choice of treatment which is generally determined by the final use that the piece will have.

To carry out the milling, Officine Meccaniche Marcucci uses innovative numerical control machines called CNC, designed for the production of prototypes, small series batches, medium series batches, for components and details made and built to customer's design.

It is the most innovative machinery and economically speaking also the most expensive because it uses a computerized system where through human intervention it communicates the instructions for the production of the piece to the machine, in such a way as to define its geometry and its path.

Administrator Marcucci says that a CNC machine favors a clear reduction in working time and greater productivity for the production of particular components in small and medium series, obviously against an investment that can lead to many advantages.

Our workshops boast the following CNC milling machines in their fleet:

Vertical 3-axis machining center

Vertical 4-axis machining center

Vertical 5-axis machining center

Our mechanical workshop offers, thanks to continuous innovations, investments and training in the processing of particular components made to design in small series and medium series, the speed and respect of times guaranteed thanks to our state-of-the-art machinery.

We offer personalized assistance in the delicate phase of prototype design, in addition to the assistance of our technical department and constant updating which for us is of considerable importance because it helps to avoid milling errors that can affect the artful realization of your design details customized components in small and medium series.

Officine Meccaniche Marcucci follows all the details and details provided by the customer taking care of all the important aspects, from the project to the delivery, we like the challenges ranging from the creation of the most complex pieces to the processing of the most challenging materials thanks to our experience in the sector.

In conclusion, if you are looking for a reliable, quick supplier for the production of parts according to drawings for small and medium series batches made of: stainless steels from the 300 to 600 series, 18NiCrMo5 39NiCrMo5 K2D K100 construction steels, C40 C43 C45 alloy steels, aluminum 7075 ergal, anticorodal aluminum 6082, brass, bronze, derlin and plastic materials used for internal processing by CNC milling in small series medium series, offering punctual shipments, you can contact Officine Meccaniche Marcucci where thanks to our technical department and our highly qualified in the metal and plastic component processing sector in small or medium batch supplies, we will be able to give you the right support for your every need, guaranteeing you the highest levels of cordiality and professionalism that still make our company grow today.

We will become your most important point of reference in the mechanical sector !!

Officine Meccaniche Marcucci